How U.S. failed GIs: Armor shortage due to Pentagon missteps

/- Originally published in the Philadelphia Inquirer on April 10, 2005 [here]

By Joseph Tanfani, Tom Infield, Carrie Budoff and Edward Colimore

Inquirer Staff Writers

When roadside bombs began killing American soldiers in Iraq, the Pentagon promised to run factories around the clock until they had enough armored vehicles.

But that didn't happen. And nearly two years and hundreds of dead and maimed soldiers later, many troops are still riding dangerous roads in Iraq without adequate armor on their vehicles.

Though the Army says all of its 35,000 vehicles on the roads of Iraq now have some sort of armor, 11,700 of them are protected with nothing more than crudely cut sheets of steel - inadequate by the Army's own standards, according to figures released Friday.

The Army intends to replace that armor, but the Pentagon says that job won't be done for five months. And the Army said Friday that combat commanders have now requested 4,000 more armored humvees and trucks.

"It just seems like it is too little, too late for these boys," said Lee Woodliff of Punta Gorda, Fla., whose son Michael, 22, was killed by a bomb a year ago in an unarmored humvee.

Just last week, a Kentucky National Guard soldier died when shrapnel came through the window of his truck. A comrade says James A. Sherrill, 27, could have been saved if antiballistic glass had been installed.

Staff Sgt. Brad Rogers e-mailed home: "Our command is saying that they are working on this issue, but I don't think they are working fast enough."

Since May 1, 2003, when the United States declared an end to major combat operations, attacks on vehicles have accounted for as many as 40 percent of the 1,037 deaths of soldiers attributed to hostile action, an analysis of Pentagon information shows.

Production and delivery of more armor, faster, might have saved lives. That conclusion is shared by soldiers, Pentagon analysts, even generals.

Why didn't it happen?

Military leaders have blamed everything from steel shortages to America's industrial decline.

But the shortage had more to do with Pentagon missteps than any lack of industrial capacity, according to an Inquirer review of documents and interviews with officers, soldiers, analysts and industry officials.

Today, its former procurement chief says the Army could have moved faster. "I would call it a success story, but it took too long to materialize," said retired Gen. Paul Kern, who headed Army Materiel Command until November.

"In retrospect, if I had it to do all over, I would have just started building up-armored humvees," he said. "The most efficient way would have been to build a single production line and feed everything into it."

Instead, Kern says, the Army went "piecemeal."

In a study completed in February, the Defense Department faulted itself: "Clearly, in some cases, such as ballistic armor for tactical vehicles, the department did not recognize the problem early enough to ensure adequate supply."

Armor did arrive - eventually. An alarmed Congress earmarked a total of $4 billion, and in 18 months, a military that had long resisted the notion of armoring noncombat vehicles put at least some armor on 35,000 humvees and trucks in Iraq. The military managed this in a procurement system in which four years is seen as quick turnaround.

Even so, The Inquirer found a record of missed chances to protect soldiers, and of unlearned lessons from previous conflicts:

Pentagon planners first called for more armored vehicles a decade ago, saying that the lessons of the "Black Hawk Down" ambush and the Bosnia conflict were that all soldiers would be targets in a new era of warfare. But the proposals got short shrift; few armored humvees were built, and no armored trucks.

For more than a year, as the toll in Iraq mounted, officials said armor production was running flat out. At Christmas, the Army's sole humvee supplier took its usual week off. The armoring plant had two four-day weekends. Owners say they could have built more - if the Army had ordered more.

The decline of steel and other heavy U.S. industry was not the main obstacle. For example: Most steel for the armor comes from the ISG steel firm's plant in Conshohocken. But ISG says it rarely got enough armor orders to run at full capacity. "Over the course of the last year we could have made a lot more," said Gary P. Sarpen, the plant manager.

The Army's own depots took a similar stop-and-start approach, making armor kits full tilt at times but then stopping as they waited weeks or months for new orders. "I don't think any of them was ever producing at their maximum capacity consistently," says Kern.

The military did not expect a fight after Baghdad fell, and, even as the sneak attacks grew in frequency and ferocity, the Army expected the insurgency to fizzle and the troops to start coming home. That meant the Army was slower to put in orders for more armored vehicles, and industry, in turn, was slower to add capacity.

The Army still hasn't fully shielded its cargo trucks. Its analysts had warned of risks to these targets, and designed add-on armor kits before the war - but the Army didn't start making truck armor until last year. It won't be done until fall, officials say.

Military officials say they worked to untangle knots in the supply chain, knowing the real price.

"I saw the result of this every day in the letters I had to sign to families, in the funerals I had to attend in Arlington, in the soldiers I visited in Landstuhl and Walter Reed hospitals," said Les Brownlee, the former acting secretary of the Army, who left in December.

"I had meeting after meeting about it and clubbed people, but I can't believe they weren't doing the best they could," he said. "There wasn't anybody taking a bureaucratic approach to this, I promise you."

To be sure, armor is no guarantee of safety. As more armor arrived, insurgents devised bigger bombs - some packed with ball bearings or other projectiles that can penetrate steel. Also, experts note, there's much more to protecting troops than cocooning them in steel. Radio jammers, even robots have been used to thwart bombs. But no one disputes armor's value.

"It could mean the fact that we can save a soldier's life," Brig. Gen. Jeffrey Sorenson said at a press briefing in December, "if we can get some of these vehicles sooner there to theater, whether it's a day, a week or two weeks."

The pace of providing armor has mystified and angered soldiers' families as well as many in Congress, who pushed for more than a year to get faster action.

Rep. Robert Simmons (R., Conn.) says the military has called armor a "top priority" since November 2003.

"Our troops in the field continue not to have the very basic steel plate that they need on every vehicle to be safe," said Simmons, a Vietnam veteran. "Why is that? What went wrong?"

Bosnia, Somalia: 'Lessons unlearned'

The answers begin more than a decade ago.

For Army commanders, the "up-armored" humvee has always been a kind of unwanted stepchild. The humvee - HMMWV, or High-Mobility Multipurpose Wheeled Vehicle - was first designed as a kind of bigger, tougher jeep for rear areas. It can carry a half-dozen troops and a heavy machine gun or grenade-launcher.

The factory-armored humvee, known as the M1114, was first built by O'Gara-Hess & Eisenhardt, a small plant just north of Cincinnati.

Prototypes were built in 1992 and flown to Mogadishu, Somalia - but too late for troops who rode unarmored humvees in the "Black Hawk Down" ambush that left 18 of them dead. "In essence, it was built because those soldiers died," said Jim Mills, a former Army program manager who worked on up-armoring the humvees.

But they got short shrift amid lean budget years and high-tech combat systems, even after Mogadishu. "I call them lessons unlearned," Mills said.

In the 1990s, a few up-armored humvees were built for scouts and military police.

In Bosnia, Douglas Callicotte and two other MPs were riding in one in 1997 when a mine blast lifted the five-ton vehicle off the ground and shredded its motor. Everyone thought the blast was fatal - until three bruised MPs climbed out.

"I wouldn't be alive if I was riding in a regular humvee," said Callicotte, who is now a car rental manager in Phoenix. "I don't know why the Army didn't invest more in them."

Generals saw them as too slow. To this day, they cite Serbian troops' 1999 capture of three U.S. soldiers in an armored humvee. "The M1114 has not really been... loved nor desired by the Army," Sorenson said in an interview. "Because (A) the incident in Bosnia. And (B) it was not determined there was a need for it."

But one of the former captives disputes that bit of Army lore.

Christopher Stone, now a Michigan National Guard lieutenant, says the armored humvee was somewhat slow, but that's not why it was captured. Stone says it lost power after Serb soldiers raked it with gunfire.

He thinks the armor saved him: "If it had been the other type of humvee, it seems to me the rounds would have gone through."

New war, new jargon: Killed by an IED

The Army first had just 235 armored humvees in Iraq. Planners did not expect a long, bloody occupation. Loren Thompson, a defense analyst, recalls an upbeat briefing on Iraq reconstruction with Defense Secretary Donald Rumsfeld and the joint chiefs of staff: "The one thing missing was the enemy."

As the invasion ended and the occupation began, humvees - smaller, more nimble than tanks or armored personnel carriers - got more use.

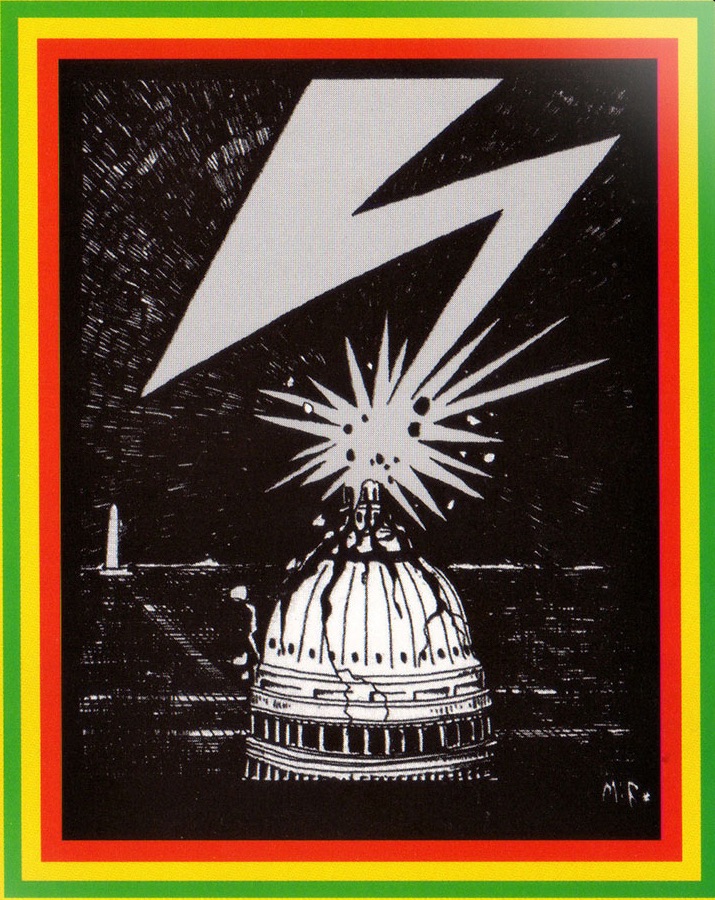

Three weeks after President Bush's May 1, 2003, "Mission Accomplished" speech on an aircraft carrier, a bomb exploded on a road near Baghdad, hitting an unarmored humvee as it escorted a convoy. The blast wounded three troops and killed Pfc. Jeremiah Smith, 25, of Odessa, Mo., a father of two girls.

It was one of the first of many attacks using crude, remotely detonated bombs - in military parlance, improvised explosive devices, or IEDs. Sorenson says, "No one, no one, predicted in the insurgency a potential" to use this tactic so widely.

From the supply side, officials said, the problem was that the armor "requirement" - what combat commanders asked for - went up in small jumps, over months, forcing them to chase a moving target.

By the time Brownlee decided that the Army needed a total of 8,105 factory-armored humvees in Iraq, the insurgency was 15 months old. And on Friday, the Army said it needed more, pushing the total past 10,000.

"I'm going to get my ass in trouble, [but] the real challenge is, there had always been an assumption, quite frankly, that the requirements would continue to tail off," said Gary J. Motsek, director of support operations for the Army Materiel Command in Fort Belvoir, Va.

By August 2003, commanders wanted more armored humvees. The goal went to 1,200, then 1,400. Because those requests were relatively modest, the Army chose to simply gather in armored humvees from bases around the world.

The IED deaths mounted.

Pfc. John D. Hart, 20, of Bedford, Mass., called his father on Oct. 11, 2003. "He was whispering into the phone, the insurgency was moving his way," said Brian Hart. "He thought he was going to be hit, and he was totally exposed in his vehicle."

A week later, Hart's thin-skinned humvee was hit by gunfire and grenades. He was killed, as was his lieutenant, David Bernstein, 1997 valedictorian at Phoenixville High School in Chester County.

Brian Hart couldn't believe that armored humvees couldn't be built any faster. He quit his drug-company job and started digging into the issue full time.

His advocacy helped propel Congress into action.

Though the Army told "congressmen and the troops that the plants were running 24/7," he said, "at not one time were those plants running full out."

The 'sad story' of sole sourcing

When it came time to mass-produce armored humvees, the Army had one place to turn: the O'Gara plant in Ohio, owned by Armor Holdings of Florida.

The humvee's maker, AM General in Indiana, builds the chassis and sends it to O'Gara, where workers replace canvas and thin metal with hard steel and antiballistic glass.

The contract was "sole source." The Army, with little interest in this work before Iraq, did not shop for other suppliers - even after O'Gara paid a $1 million fine in 2000 to settle a "whistle-blower" lawsuit over defective welds.

"It's a sad story to report to you, but had we known then what we know now, we would probably have gotten another source involved," Pentagon acquisition chief Michael Wynne testified to Congress a year ago.

The need became urgent.

"Every day, our soldiers are killed or wounded in Iraq - by IEDs, RPGs, small-arms fire. Too many of these attacks are on HMMWV's that are not up-armored," the Army's Brownlee wrote on Oct. 20, 2003. "While we may already be expediting up-armored HMMWVs... we are directing that all measures to provide protection to our soldiers be placed on a top priority, most highly urgent 24/7 basis."

The memo went out to humvee suppliers. On Friday morning, a copy was still on the bulletin board at the ISG steel plant in Conshohocken.

But 24/7 didn't quite happen. Until January, the ISG plant had capacity that the Army never consistently used, says Sarpen, the plant's general manager.

In November 2003, Sen. Ted Kennedy (D., Mass.) grilled Brownlee about armor delays, noting that three Massachusetts troops had died in unarmored humvees: "Are they running their plant 24 hours?"

Brownlee said the O'Gara plant in Ohio was running at "maximum capacity."

But it wasn't. Army documents show that monthly armor production at O'Gara fell after that - from about 55 to 45 humvees, in December.

By early 2004, O'Gara officials were telling members of Congress that they could armor vehicles much faster - if they had a commitment to buy them.

Rep. Simmons says he toured the plant a year ago and found their antiballistic-glass operation working just one shift, "so they obviously weren't at capacity."

O'Gara spokesman Michael Fox declined to discuss details, but said, "There's no doubt if you knew on day one you would need 8,000 [armored humvees], you would have done things differently."

Fox says the plant "would have ordered all the steel it needed at one time. It would have hired all employees it needed at once."

The Army's Brownlee visited the O'Gara plant in February 2004, and struck a deal: If the plant ramped up to 450 armored humvees a month, he would find money to buy them.

But there was still reluctance to have O'Gara go flat out.

Former Army Comptroller Dov Zakheim says the worry was that O'Gara, in stepping up production, would get sloppy: "People would have said, 'Look at the Department of Defense, wasting all this money.' "

Scrounging for armor - in the defense budget

When O'Gara couldn't armor humvees fast enough, the Army decided to try to quickly get a kit - steel doors and antiballistic glass - made at its own depots, a nationwide system of factories left over from World War II.

The Army has three levels of armor. Level 1 is a brand-new, factory-made humvee. The factory-made kits are known as Level 2, with thick steel doors and antiballistic windows, shipped to the combat zone and added to trucks or humvees. Some of these have floor armor, some not - an important difference because nearly three dozen troops in vehicles have been killed by blasts from below, records show.

Level 3 is a temporary fix and offers the slimmest protection: steel cut from sheets and hung or bolted on.

At the Army's own depots, Motsek says, managers bent procurement rules to make kits faster.

"Normally, in acquisitions programs, you do it in six and eight years, that is considered a success story," he says. "This was done in a matter of months." He calls criticism of the pace of production "a cheap shot."

But even at the depots, the effort was bedeviled by funding gaps and cautious, incremental orders. One issue: While Congress was throwing money at the armor problem, the Army didn't always spend it quickly. The Army says it had to get budget approvals - creating, at times, weeks of delay.

It wasn't until December 2003 that the Army came up with money for a large order of humvee armor kits.

When the orders arrived, crews sweated to crank them out. At Letterkenny Army Depot in Chambersburg, Pa., an armor crew worked around the clock from Jan. 4, 2004, to April 27 with one day off - Easter, said Col. Bill Guinn, Letterkenny commander.

But in spring of 2004, Letterkenny and the other depots significantly slowed their armoring kits lines. Why? Orders tailed off. The depots had built what the Army had requested, about 8,900 kits. An additional 1,000 were built over the summer.

In August, the Army decided it needed almost 4,000 more kits - but again, two months passed as the Army scrounged for the money.

The armoring lines at Letterkenny didn't start moving again until December. Now, they are making armored cabs for five-ton Army trucks - but are not slated to be done until August.

The army you have: Rumsfeld's firestorm

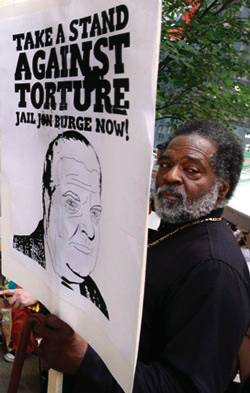

The armor issue entered a new age on Dec. 8 when a Tennessee soldier, Thomas Wilson, stood up and asked Rumsfeld why his unit had to scrounge for scrap armor.

Rumsfeld said the military was addressing this problem. But part of his answer - "you go to war with the army you have" - created a firestorm.

Things changed in a hurry, starting at O'Gara. The company had reached its goal of 450 armored humvees a month by September, and announced that it could add capacity.

When Rumsfeld said armored humvees couldn't be built any faster, O'Gara officials told reporters they actually could build 100 more a month.

That was news to the Army, said Sorenson and others. But records and interviews show that O'Gara had been saying months earlier that it could push production faster.

The next day, the Army agreed to fund a faster production rate, to 550 armored humvees a month. That is what O'Gara is producing now.

The ISG plant in Conshohocken got the message, too. "That was the most intense part of armor production that we saw in the past year and a half," ISG's Sarpen said. "It got very heavy, very fast."

The calls came from contractors, not from the Pentagon, he said. Suppliers feared being labeled "the next company that 'couldn't produce the armor quicker,' " Sarpen said.

Meanwhile, the Pentagon formed a task force to get Navy and Air Force machinists and welders working on armor in Iraq. It is headed by an Air Force general who reports to Rumsfeld twice a week.

Bryan Whitman, a Rumsfeld spokesman, said Friday: "The Secretary of Defense does not decide how much or when the Army buys its equipment."

Snags persisted. Two days after the Rumsfeld episode, Rep. Gene Taylor (D., Miss.) said he visited the Rock Island, Ill., arsenal and found just three people working on armor - two cutting steel, one welding.

AM General, the Indiana humvee maker, closed from Christmas to Jan. 2. That break, routine in the auto industry, is in union contracts, the company said.

O'Gara's humvee line also halted for two four-day holiday weekends. The plant was shutting down when a reporter visited in early afternoon on Dec. 30, and was closed all day Dec. 31.

At peak production, the humvee line runs two 10-hour shifts, five days a week, but not weekends. The line "doesn't run 24 hours a day," Fox said. Nonetheless, he said, O'Gara was "several hundred vehicles ahead of [Army] contract requirements."

On Feb. 17, Rumsfeld told Congress that "with very few exceptions" no unarmored vehicle would enter Iraqi danger zones.

But many vehicles labeled "armored" by Rumsfeld are at Level 3, with a few steel plates, cut in the field and bolted or latched on. Many still don't have antiballistic glass. Upgrading all of them will take months.

By September, the Pentagon aims to have all vehicles in Iraq sheathed in better armor.

Rogers, the Kentucky National Guard sergeant who wrote the e-mail from Iraq about Sgt. Sherrill's death, said his men would be riding the same roads yesterday with only "hillbilly armor" - steel panels on two sides of their trucks.

"I think this is something the public needs to know," he wrote. "Most of all, please continue to pray for us."